March 02, 2023

ASTEC Digital's Successful Plant Software Suite Prioritizes Plant Operators

What is behind our customers’ enthusiasm for our software, and what makes ASTEC Digital a leader in advanced customizable asphalt plant control systems?

After years of effort, ASTEC Digital is seeing its innovative suite of software solutions enjoy growing success in the U.S. market. What’s behind our customers’ enthusiasm for our software, and what makes ASTEC Digital a leader in advanced customizable asphalt plant control systems? It’s a decision we made at the very beginning, which has consistently guided our product design: we see plant operators as our customer base.

We decided that our plant control systems needed to be perfect servants to plant operators, faithful and extremely competent helpers who would take care of control tasks without ever becoming overreaching, imposing on workflows, or restricting what operators could do. In other words, the system had to mould around the operator rather than asking the operator to mould himself around the system. This decision has impacted every choice we made, from the human interface, the signal interface, the type of wiring, the choice of the technology platform, and more.

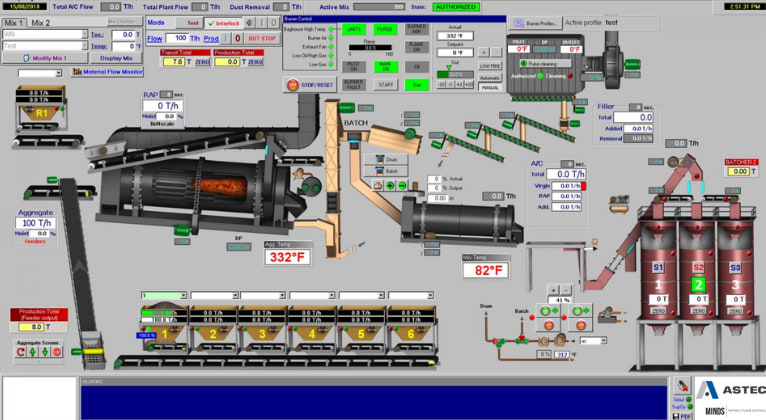

This way of thinking is evident in ASTEC Digital’s DrumTronic and BatchTronic asphalt plant automation and control systems. Our reliable, accurate, and customizable plant control systems were designed after consultations with actual plant operators and give them the level of fine-tuned automation and control they need to get the most out of their plants.

Assisting the operator and making his life easier could have cut him off from “feeling” the plant, and this led to the second key decision that guided the product-development ethos for our plant control systems: helping the operator stay connected to the physical plant.

Making asphalt is a physical and chemical process, and production control software should not take away from that. The electronic and computer interfaces between the operator and the process are just that: interfaces. We believe they should be minimized and made forgotten to make the underlying physical process stand out clearly. For example, when displaying a flow rate for a weighed conveyor belt, we display ft/min for the speed and lbs./ft for the weight. If someone wants to check, it is easy to zoom in on that belt, take a measurement of the speed with a tachometer, stop the belt, take a one-foot sample, and weigh it. That makes it easy to see that the product of lbs./ft x ft/min = lbs./min, which is indeed flow rate. Obviously, stopping a conveyor belt to weigh a section is no longer a practice nowadays, but our approach illustrates the idea of sticking as closely as possible to the physical reality of the process and avoiding the use of opaque units, such as "points" for a weight or "pulses" for a speed.

Another area that significantly helps the operator to stay connected to the physical plant is our choice of graphic representation. An ASTEC Digital system graphical signature is remarkable in its depiction of each plant's actual look and configuration layout, which our team customizes for each client, to help plant operators more easily visualize their operation. DrumTronic and BatchTronic also do away with vast arrays of numbers in favour of clear symbols to demonstrate important plant metrics. This “more real than life” look is not just done for aesthetic purposes: it helps make the interface disappear.

Another aspect into which we put a lot of effort is to qualify the process in real-time using all redundant data as an early indication of drifts or upcoming problems. For example, we check that the ratio of the setpoint voltage of the drives to the flow or speed of the controlled element remains within acceptable proportions that are established during the plant calibration. This is the prelude to the use of artificial intelligence, whereby the correlation of indirect indicators to the main sensors will be established during a learning phase and then systematically verified during production. All these techniques allow us to detect drifts symptomatic of potentially serious problems. The idea is that if the process is working properly and the raw materials entering the process are of good quality, then the output product is likely to be of good quality as well.

There are many more reasons our plant control system stands out from the crowd: the choice and design of our IO devices, the reduction of electronics or software components to minimize failure rate, and new improvements like real-time signal credibility assessment and process models. We invite you to browse our website to learn more about the philosophy and principles behind our asphalt systems.