March 05, 2024

Maryland asphalt producer uses ASTEC Digital’s PM3 controls to lower the carbon footprint of its asphalt mixes

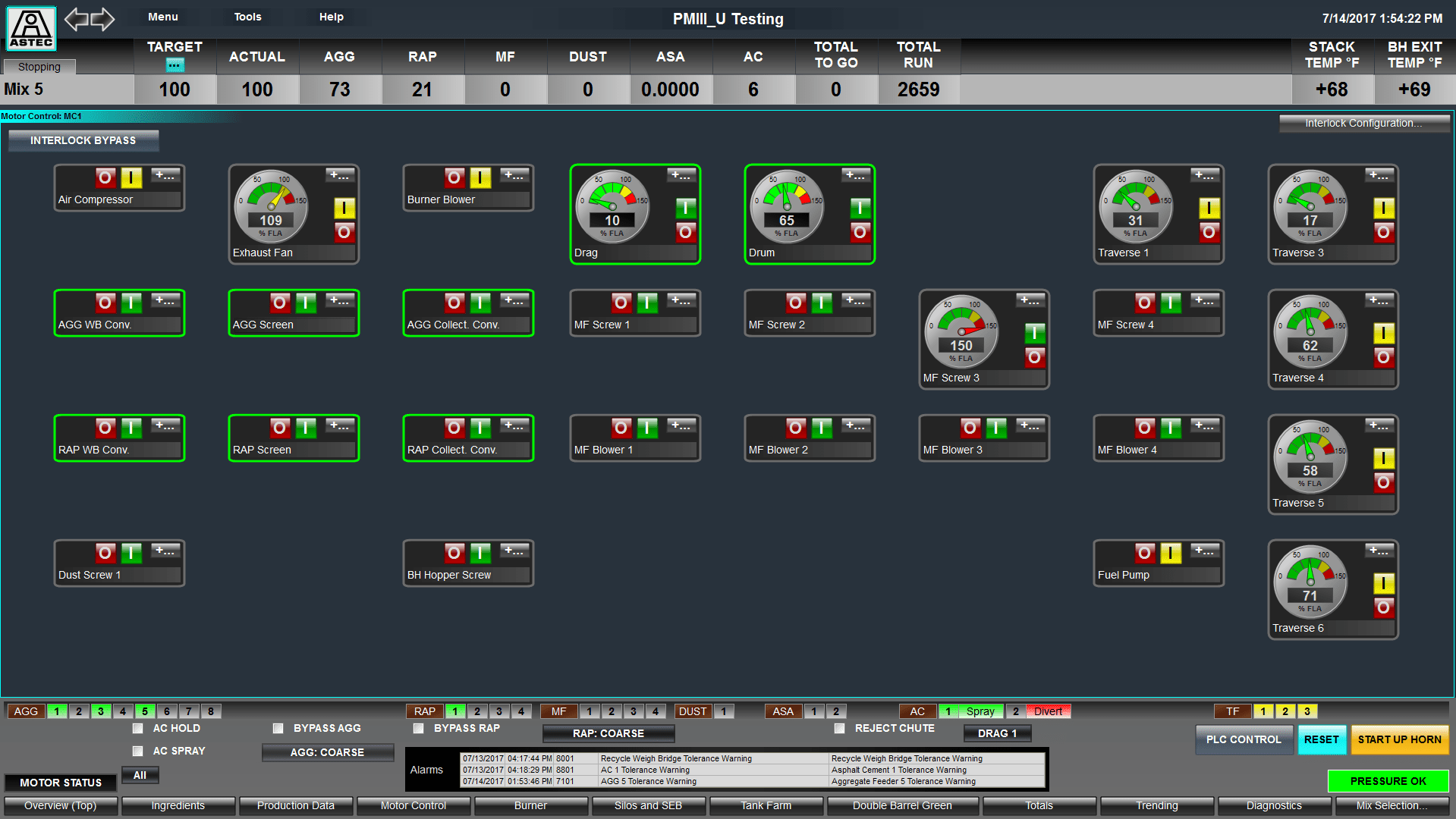

ASTEC Digital’s PM3 asphalt plant controls have precise burner controls and other features that have allowed Laney Construction materials to reduce the carbon footprint of its operation.

The asphalt industry is facing more stringent environmental requirements, with the introduction of environmental product declarations (EPDs) in the 2021 Infrastructure Investment and Jobs Act requiring asphalt producers to quantify the emissions and other environmental impacts of their asphalt mixes. Laney Construction Materials, an asphalt producer in Woodbine, Maryland, is relying on ASTEC Digital’s PM3 asphalt plant controls to ensure its mixes are as energy-efficient as possible.

“Where we’re at today and going to be advancing to in the future, we’re an industry that’s very focused on low-carbon technology,” says Jeff Graf, the general manager of Laney’s asphalt division. “PM3 allows you to meet the stringent mix requirements [of clients] and also the environmental requirements.”

Laney, which has two asphalt plants and offers more than 100 asphalt mix designs and specialty asphalt products, installed PM3 in late 2021 after upgrading one of its plants from an old asphalt batching plant to an ASTEC double barrel drum mixer plant. Graf says the company also invested in the ASTEC Digital software because after years of only having asphalt blending controls, the company wanted total plant control and to move away from mechanical logic controls to PLC logic.

As Laney is increasingly focusing on its EPDs, Graf says the company has been evaluating how it can drive down the carbon footprint of its asphalt products. The PM3 software has enabled Laney to use variable frequency drive on various components to improve its energy efficiency, and PM3’s ultra-precise burner controls have enabled the company to fine-tune its burners for maximum fuel efficiency and cleanliness.

As part of Laney’s low-carbon evolution, the company is using a greater percentage of recycled asphalt products — roughly 40 percent or more — in its mixes. The PM3 controls have allowed the company to customize the percentage of RAP depending on the mix, using ASTEC’s warm mix technology to make those mixes at lower temperatures, further reducing its fuel consumption and emissions.

Compared to the previous blending controls that Laney’s used, Graf said PM3 is much more user-friendly. “PM3 advances what you can do in mixes, especially when you look at additives, recycled asphalt product, all those things our industry is leaning toward,” he says, highlighting the ability to do more custom mixed designs, to tailor the plant operations process and precision blending controls that keep its mixes continuously in spec.

Graf says he regularly tells colleagues in the asphalt industry about ASTEC’s service-oriented ethos and decades-long commitment to innovation.

“Knowing that I have a strong support system like ASTEC at the table, that has a lot of value to me, and it’s one of the reasons I’ve utilized their services and their equipment a lot in my career,” he says. “Don Brock was always a strong supporter of industry advancement, and that’s very important to me. They look at advancements and really focus on what we do in the industry.”

Product

ASTEC Digital’s PM3 asphalt plant controls.

Application

Laney Construction Materials’ two asphalt plants in Woodbine, Maryland.

Challenge

With the 2021 Infrastructure Investment and Jobs Act introducing environmental product declarations for asphalt products, Laney Construction has been focusing on driving down its mixes' carbon footprint and environmental impacts.

Solution

Laney installed the PM3 asphalt software after a plant upgrade in late 2021 as it also sought to move from just blending controls to a total plant control system.

Results

The PM3 controls have allowed Laney to use variable frequency drive energy controls on various components in its plants, optimize the energy use of its burners, customize the amount of recycled asphalt product it uses in its mix, and more energy-saving initiatives that have kept its EPDs low.

Optimize your operations with intuitive, precise, intelligent asphalt plant control systems. ASTEC Digital’s telematics and plant control systems simplify and improve plant management for the asphalt industry. Visit our website to learn more.