March 05, 2024

Switching to ASTEC Digital’s PM3 controls improves calibration for Louisiana hot mix asphalt producer and paving contractor

The calibration capabilities of ASTEC Digital’s PM3 asphalt plant control system helps Madden Contracting meet the strict requirements of the transportation departments it works with.

Madden Contracting Company knew its asphalt plant control system was outdated: it was controlled by outdated componentry, challenging for plant operators to use, and so old that components were no longer available on the market if one needed to be replaced. Given its age, the accuracy of its mix calibration wasn’t as good as that of newer systems. So, in 2020, the company upgraded one of its Louisiana sites to ASTEC Digital’s PM3 hot mix asphalt plant software. After seeing success, it made the switch to a second location.

“PM3 brought us into the present day,” said Keith Alton at Madden. “It’s a lot easier for the plant operators to actually run the plant and calibrate the plant.”

Madden is a significant hot mix asphalt producer and paving contractor across Louisiana and east Texas, focusing on highway asphalt road construction, particularly large interstate and highly technical projects. The company has four hot mix plants in Louisiana.

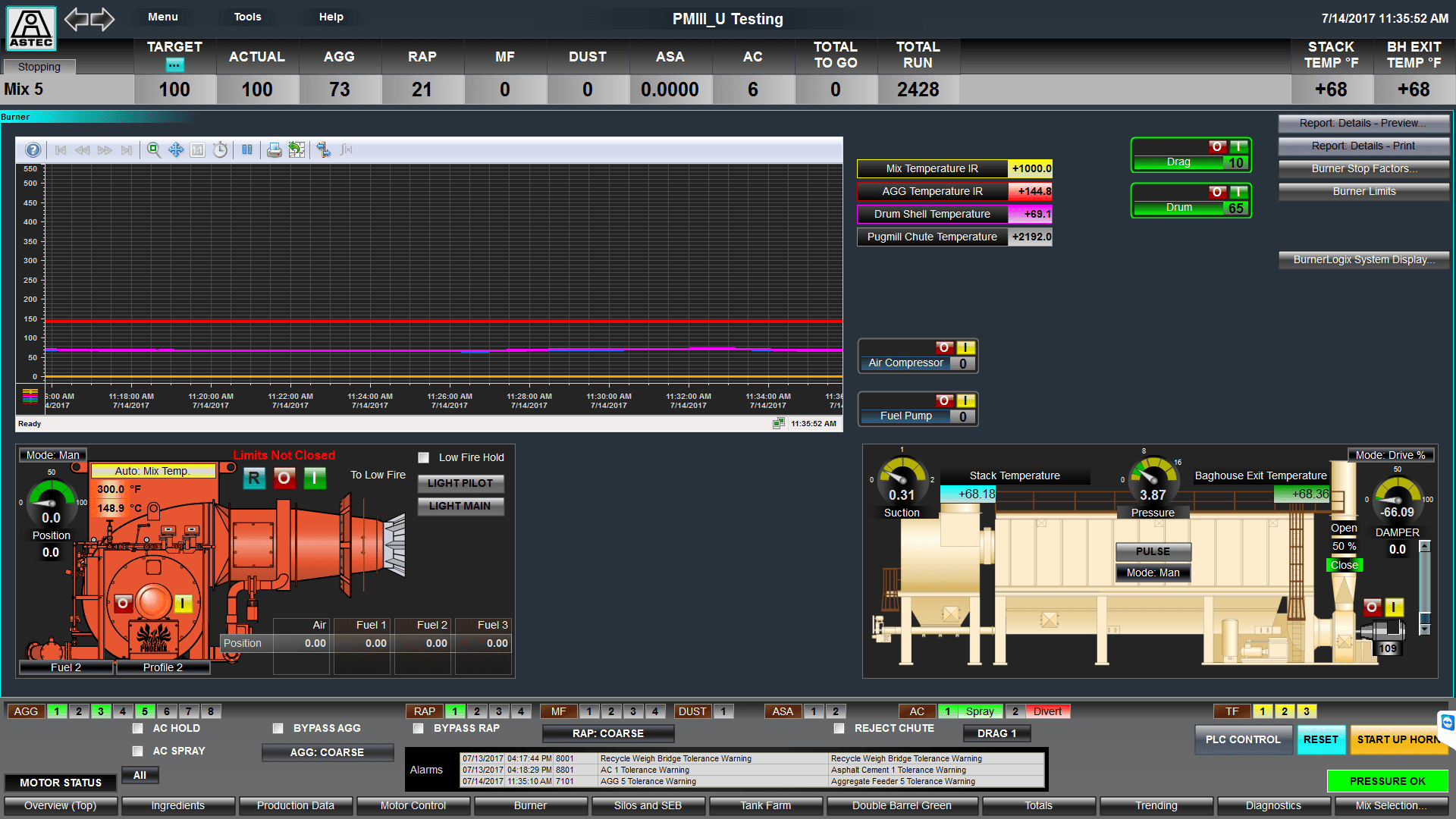

ASTEC Digital’s PM3 is a PLC-based hot mix asphalt plant control system. The system has advanced asphalt blending controls that cover eight virgin aggregate VFD bins and a virgin aggregate scale, one additive, an asphalt metering system, calibration for all scales, pumps, and feeders, mix design tolerances and start-stop timing, and more. The system also offers baghouse and burner controls and alarms for any system errors.

Alton praised PM3’s calibration capabilities and material mix design tolerances in particular. Madden’s asphalt, he noted, is held to a high standard by state transportation departments to ensure that the roads they pave are safe and long-lasting for drivers. If their mix deviates from those standards, the cost implications for the company are significant. “It has to be mixed precisely; we need to be making the best quality asphalt,” he said.

He said the system is also much easier for plant operators to use. Unlike Madden’s old system, which couldn’t connect to the internet, PM3 allows the user to go online for any updates or fixes and is “modern and adaptable” to the needs of the plant.

Alton said the PM3 system’s high reliability and uninterruptible power supply is a game-changer, given that if the system were to go down, every lost hour of production would cost Madden roughly $30,000. “The quicker up-time has been a major benefit; it’s way more reliable,” he said. From a maintenance perspective, he added that he appreciates that ASTEC does have a large stock of parts available if one breaks down and that the company is responsive to service requests.

Product

ASTEC Digital’s PM3 hot mix asphalt controls.

Application

Two of Madden Contracting’s hot asphalt mix plants in Louisiana.

Challenge

Madden wanted to replace the old and outdated computer system that was controlling its plants to improve its calibration capabilities and the precision of its asphalt mixes.

Solution

Madden installed ASTEC Digital’s PM3 asphalt plant control system at one of its sites in 2020 and has since installed it at a second plant.

Results

The PM3 controls have improved Madden’s mix calibration and made it easier for plant operators to run the plant. The paving contractor also appreciates the system’s internet-enabled capabilities, uninterruptible power supply, and superior customer service from ASTEC Digital.

Optimize your operations with intuitive, precise, intelligent asphalt plant control systems. ASTEC Digital’s telematics and plant control systems simplify and improve plant management for the asphalt industry. Visit our website to learn more.