Highlights

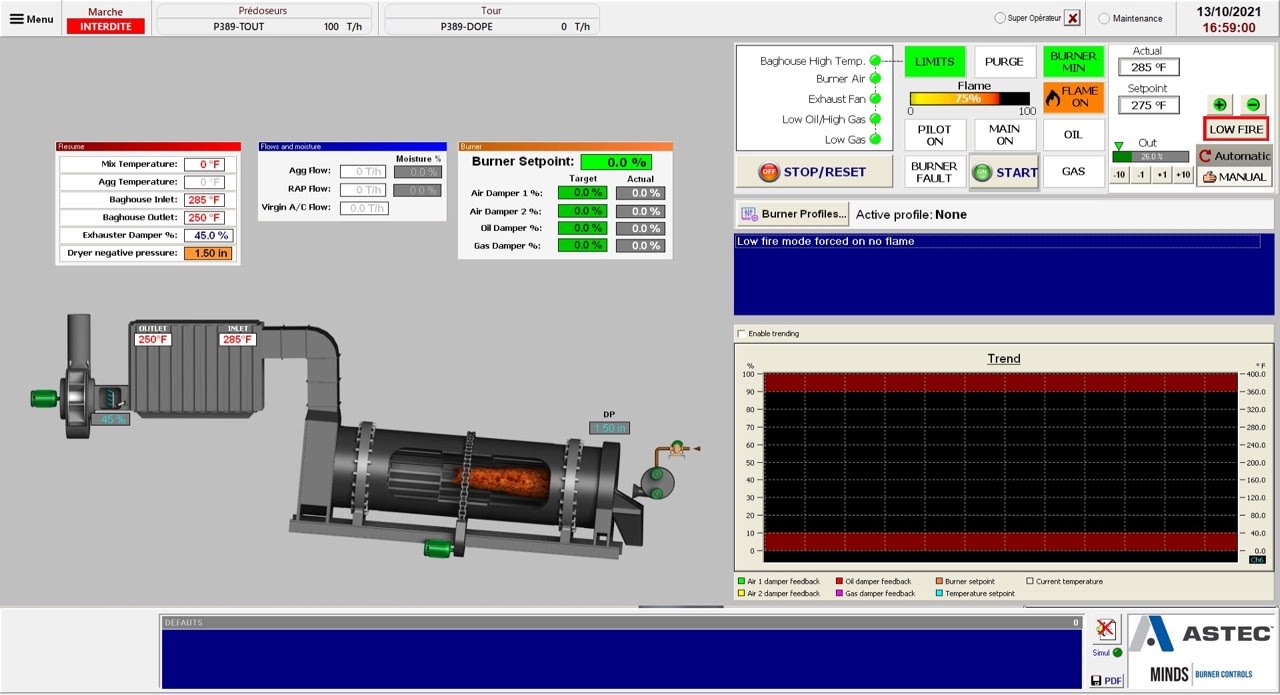

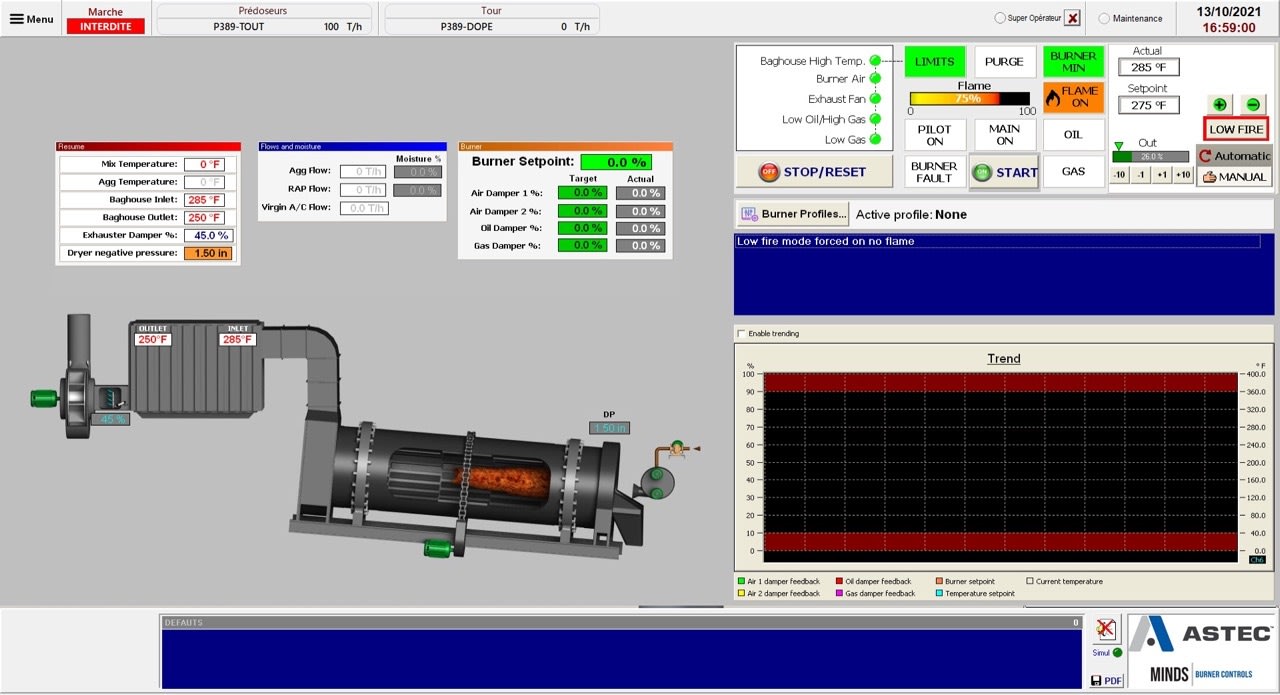

DrumTronic Burner Control Highlights

The DrumTronic Burner Control is a versatile, advanced system offering four analog or digital channels for an easy retrofit of any burner. The controls can be finely tuned and profiled with separate air and fuel ratio control points—twice as many as what is found on the market, allowing for maximum efficiency and precision, from light-off through to 100 percent firing rate. The DrumTronic Burner Control can use direct coupled actuators or any standard drive motor in any combination one can imagine. The system achieves flame safety with Honeywell or Fireye flame relays, readily available and proven solutions with a long history of dependability and cost effectiveness. Redundant high-stack temperature safeties, both hard-wired and software-driven, protect the baghouse from excessive heat. The burner safety chain is wired for first-out status and easy troubleshooting. Burner Controls are UL-listed and NFPA-compliant.

Features

- Multi-actuator, multi-fuel, profiled control points

- Can be integrated into asphalt plant control software or bought as a standalone version

- Easy and intuitive user interface

- UL Listed and NFPA-compliant

- Low cost, easy retrofit of any burner

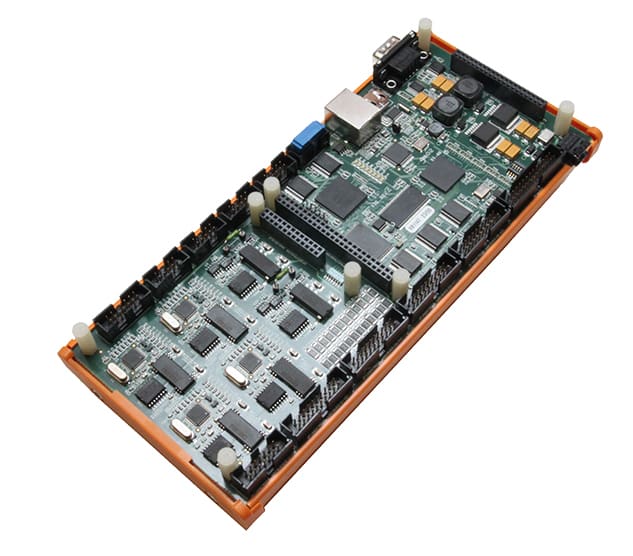

XIO Controller

Dedicated hardware for inputs & outputs

All the electrical inputs and outputs of our asphalt plant control systems are handled through one or many instances of a single type of electronic board: the XIO controller. A small asphalt batching plant requires just a single one, while a very large drum plant may require upwards of five boards. Employing one type of I/O board means there is just one model to manufacture, stock, maintain, and support. We have deployed thousands of them at hundreds of plants on four continents. Learn more here.

The ASTEC Digital data suite, Connectivity Suite, brings together all of the digital offerings into a single standardized platform from ASTEC. Our intention and objective are to be a digital solution provider of choice. As our offerings evolve, we are committed to our Rock to Road customers. We vow to remain a customer-focused entity, developing durable solutions to help our customers on their journey.