Highlights

Highly Efficient, Computerized Plant Controls

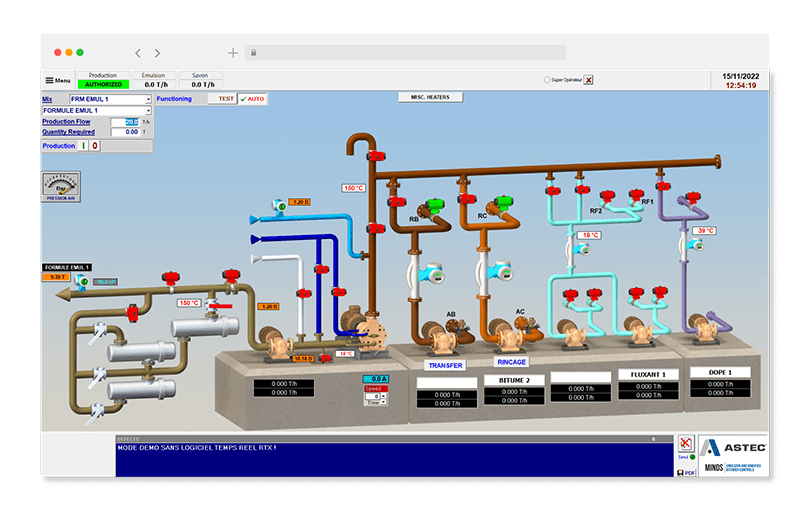

EmulTronic is an advanced emulsion plant control system, modified bitumen control system, and liquid terminal control system. All functions of running a terminal or plant are handled, from unloading trucks or rail cars of raw materials to mixing and blending, storing, heating, loading out, and printing tickets of the finished product. Multi-screen operator-oriented 3D definition graphics reduce the learning curve and assist with troubleshooting. The on-screen configurable system allows multi-parameter editing without reprogramming. Easy and reliable calibration procedures ensure conformance to the most strict standards. The system can be set up with or without manual controls in parallel to the automation inputs and outputs.

Highlights

Clearly See Your Operations

The EmulTronic is scalable and fully expandable to adapt to existing production facilities as well as high-end, modern, fully integrated production plants. The human interface shows the exact configuration of pipes, valves, pumps, mixers, tanks, etc. Both batch and continuous processes can be accommodated. All important information is readily available for an easy and straightforward understanding of the plant's status.

Highlights

Worldwide Proven Performance

With happy customers around the globe, the proven EmulTronic adds a level of automation that can be adapted to any budget and plant complexity. It’s an industrial computer, and ruggedized I/O boards give it the robustness needed in the harsh environment typical of emulsion plants. ASTEC has solutions to visualize your operation remotely for ultimate control. Our automation software can also be linked to TicketManager so managers can see a high-level overview of totals, consumption, and inventory usage. Contact us for customer references regarding large and smaller projects.

Quick Tour

Specifications

- Fully adaptable to any plant, unlimited expandability

- Realistic plant representation with 3D high-definition graphics

- Consistent, high-quality production control

- Intuitive interface minimizes the operator learning curve

- Easy, fast, and reliable calibration procedures

- Precise real-time production and flow control

- Complete automatic production control with manual bypass capabilities

- Production logging and traceability

- Ultrafast process regulation for outstanding quality control

- Raw/Finished product tank management

- Control of tank heating

- Fully integrated loadout and ticketing when combined with Loadtronic

- Optional backup hard disk drive for virtually no downtime

- Optional integration with accounting/billing systems through TicketManager

Emulsion and PMA Controls Hardware

EmulTronic isn't just software. It's a complete solution with dedicated hardware behind the scenes. The EmulTronic Cabinet is comprised of an industrial PC, one or more instances of our XIO Control Module, plus hard drives and backup drives. Employing one type of I/O board means there is just one model to manufacture, stock, maintain, and support. We have deployed 1000s of them at 100s of plants on 4 continents. Learn more here.

ASTEC Digital's hardware advantages for your emulsion plant:

- ASTEC Digital's custom hardware has been designed and continuously updated for over 20 years, ensuring continuity and support

- Single board plug and play (XIO) replacement parts

- Industrial plant computers and double backup systems virtually guarantee no downtime

- EmulTronic software customization included

The ASTEC Digital data suite, Connectivity Suite, brings together all of the digital offerings into a single standardized platform from ASTEC. Our intention and objective are to be a digital solution provider of choice. As our offerings evolve, we are committed to our Rock to Road customers. We vow to remain a customer-focused entity, developing durable solutions to help our customers on their journey.