Highlights

Unique architecture

The XIO module is a multiple input/output controller used in our automation and control systems. This module is characterized by its unique architecture, compactness, and robustness and uses a TCP/IP communication protocol over an Ethernet link. The XIO module is equipped with logic input and outputs, analog and frequency input-outputs, each type in a calculated proportion that just one type of module is needed to control an asphalt plant. Thus, a small application requires one or two XIOs. Additional XIOs, identical to the first one, can be added to increase the number of input-outputs to increase capacity. A very large plant with comprehensive automation can require six XIOs or more.

The advantages of this architecture are numerous:

- Only one module is needed as a spare part

- Guaranteed flexibility and extensibility

- Simplified systematic wiring

- Support and maintenance facilitated

- Inherent generation of spare inputs and outputs

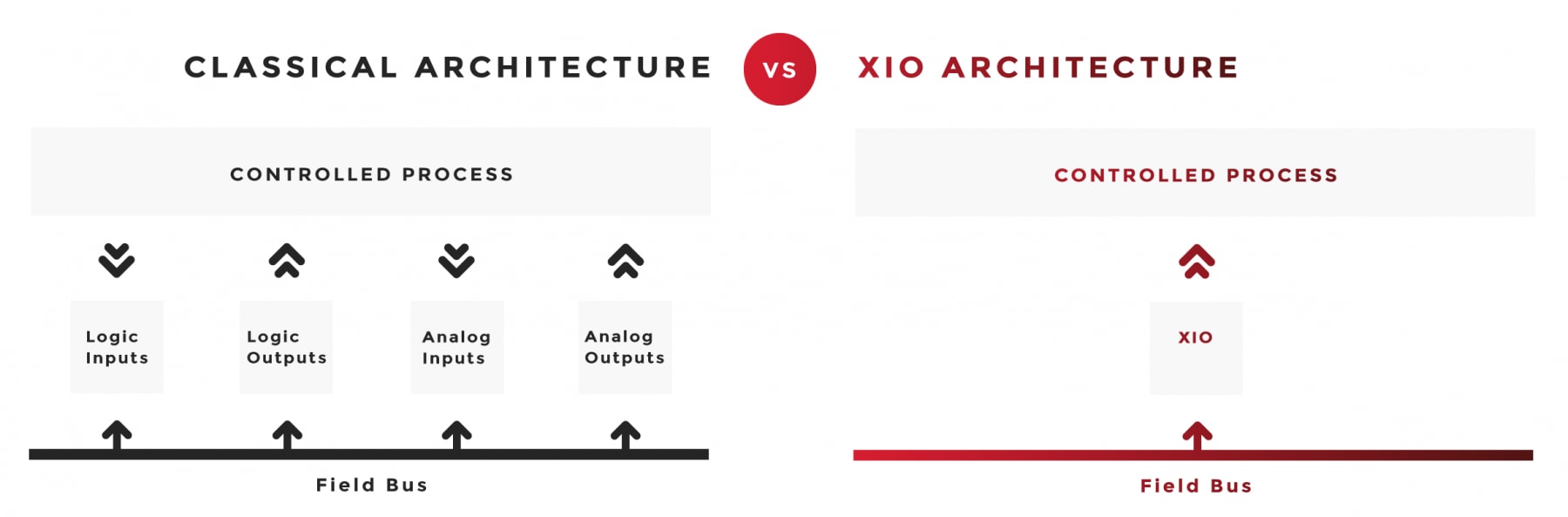

Comparison With Traditional Architecture

In a traditional installation using a field network, electronic modules ensure the input-outputs are specialized according to the type of signals: logic inputs, logic outputs, analog inputs, analog outputs, etc. This architecture multiplies the number and types of electronic modules (refer to Classical Architecture). With the XIO, only one standard device is necessary, with all input-output types onboard (refer to XIO Architecture). When the number of input-outputs is very important, the cost of the two solutions is similar. Still, on small and average installations, in an example of road construction plants, the architecture of XIO reduces costs and becomes more profitable. In all cases, spare parts management is much easier with the XIO architecture.

Specifications

- Two (2) isolated analog outputs (six (6) with optional extension)

- Four (4) isolated analog input (12 with option extension)

- 32 scalable up to 56 logic outputs

- 40 scalable up to 64 logic inputs (or analog inputs, individually configurable)

- Six (6) quadrature/12 single optical encoder inputs

- 2500 Vrms isolation (1 min)

- Ethernet communication

- DIN Rail mounting

- Operating temperature: 0 to 50 °C (32 to 122°F)

- Humidity: 5 to 95% non condensing

- Storage temperature: -40 to 85°C (-40 to 185°F)

- Dimensions mm (inches): 240 (9.4) x 105 (4.1) x 41 (1.6)

- 12 bits, 0-10V, maximum load = 2kΩ

- Differential nonlinearity (DNL) = +/- 0.5 LSB

- Integral nonlinearity (INL) = +/- 3.5 LSB

- Offset error = +/- 4 mV

- Full scale error = +/- 2 LSB

- Accuracy = 10V +/- 0.1%

- Noise < 1ppm p-p (0.1Hz – 10Hz)

- Short circuit protection by fuse (62.5mA)

- 24 bits (NO MISSING CODE)

- INL: 0.0012% of full scale

- Measuring Scale: 0-20mV, 0-40 mV, 0-80 mV, 0-160 mV, 0-320 mV, 0-625 mV, 0-1.25 V, 0-2.5 V, 0-5 V, 0-10 V

- Automatic calibration

- Maximum common mode voltage = 50V (limited by the ceramic capacitor)

- Common mode rejection = 120dB

- Normal mode rejection (60Hz or 50Hz) = 100dB

- Input impedance: 400kΩ

- Open drain output type

- Short circuit protection: 0.9A

- Over temperature protection

- Short circuit and open load detection for each output

- Over-voltage protection

- 25ms switch debouncer

- 24V input with 4V threshold

- Possibility of 64 non-isolated current (4-20mA) inputs

- 12 bits (NO MISSING CODE)

- Integral Linearity Error = ±2 LSB

- Differential Linearity Error = ±0.8 LSB

- Offset Error = 10mV ±3 LSB

- 2.5V Reference

-Accuracy = 2.5V +/- 0.2%

-Noise = 35μVrms (typ) (10Hz – 10kHz) - Maximum input voltage = 3.3V

- Six (6) inputs over two (2) channels (quadrate decoder mode) or 12 inputs over one (1) channel

- Digital glitch filter on each input

- 16 bit counter

- Configuration: counter mode/frequency mode

- Accept all types of inputs (open drain, open emitter, totem pole, push-pull)

- Input current = 10mA

- CPU 66MHz, Coldfire 32bits with 1kbyte cache memory

- 16 MB of SDRAM (32 bits)

- 8 MB of FLASH (16 bits)

- One (1) Ethernet port 100Mbits

- One (1) RS232 Serial port

- One (1) Real-time clock

- One (1) Reprogrammable FPGA

- One (1) 3.3V 2A Power supply

- One (1) 5V 2A Power supply

- One (1) 1.5V 1.2A Power supply

- Analog modules are isolated from one another

- Isolation barrier = 2500Vrms

The board has two buses. The first is for CPU bus extensions, where you can add a peripheral card like USB, touch screen monitor, mouse, RS-485, etc.

The second bus is an SPI type and has the ability to connect two external cards, providing two (2) analog outputs and four (4) analog inputs each. The electrical characteristics of those modules are the same as the ones on the motherboard.

The ASTEC Digital data suite, Connectivity Suite, brings together all of the digital offerings into a single standardized platform from ASTEC. Our intention and objective are to be a digital solution provider of choice. As our offerings evolve, we are committed to our Rock to Road customers. We vow to remain a customer-focused entity, developing durable solutions to help our customers on their journey.